Lean Principles in Product Development: Streamlining the Process

Lean principles originated in manufacturing and have since been applied to multiple industries, including software development, healthcare, and services. The core idea behind lean is to maximize customer value while minimizing waste. The main concern of lean thinking is eliminating waste, enhancing efficiency, and continuously improving processes. Applying lean principles to product development can result in a well-structured and more effective approach. Here's a comprehensive explanation of how lean principles can be integrated into the product development lifecycle.

Value-Driven Development:

Lean product development begins with a focus on delivering value to the customer. Identifying and understanding customer needs is the most crucial factor. This involves active communication with customers to understand their requirements and preferences. Also, ensures that the product addresses real needs and provides tangible value.

Eliminating Waste:

One of the essential principles of lean thinking is the elimination of waste. In product development, destruction can present in various forms, such as excessive documentation, redundant processes, or unnecessary features. Streamlining the development process involves identifying and eliminating these wasteful elements, allowing resources to be utilized more efficiently.

Cross-Functional Collaboration:

Lean encourages forming cross-functional teams where members from different departments collaborate throughout the product development lifecycle. This reduces delays caused by handovers between groups and enhances communication. Also, it ensures that diverse perspectives are considered, fostering innovation and problem-solving.

Iterative Development and Rapid Prototyping:

Instead of long development cycles, lean principles advocate for iterative development and rapid prototyping. However, this approach allows for quick testing and validation of ideas. It reduces the risk of investing resources in a direction that may not meet customer expectations. Iterative development also helps in adapting to changing market conditions and feedback.

Pull System:

Implementing a pull system in product development means starting work on a new task only when there is a demand for it. This prevents overproduction and ensures that resources are allocated based on actual needs. It also helps prevent unnecessary work on features or components that the customer may not require or value.

Visual Management:

Visual management tools help teams visualize their work, identify bottlenecks, and manage workflows more effectively. Hence, these tools provide transparency into the development process. Also, it allows teams to make data-driven decisions and optimize their work to enhance efficiency.

Continuous Improvement:

Continuous improvement is a core principle of lean thinking. Product development involves regularly reflecting on the development process, gathering feedback, and making incremental improvements. However, encouraging a culture of continuous improvement fosters innovation. Also, it ensures that the development process remains adaptive and responsive to evolving needs.

Set-Based Design:

Rather than committing early to a single design, lean product development often involves exploring multiple design options simultaneously. Hence, this set-based approach allows teams to delay decisions until more information is available. It helps reduce the risk of investing heavily in a design that may prove insignificant later.

Flexible Resource Allocation:

Lean principles emphasize the need for flexible resource allocation. This involves having a workforce that can adapt to changing project requirements. It also helps in allocating resources based on the project's current needs. Hence, this flexibility helps in optimizing resource utilization and maintaining efficiency.

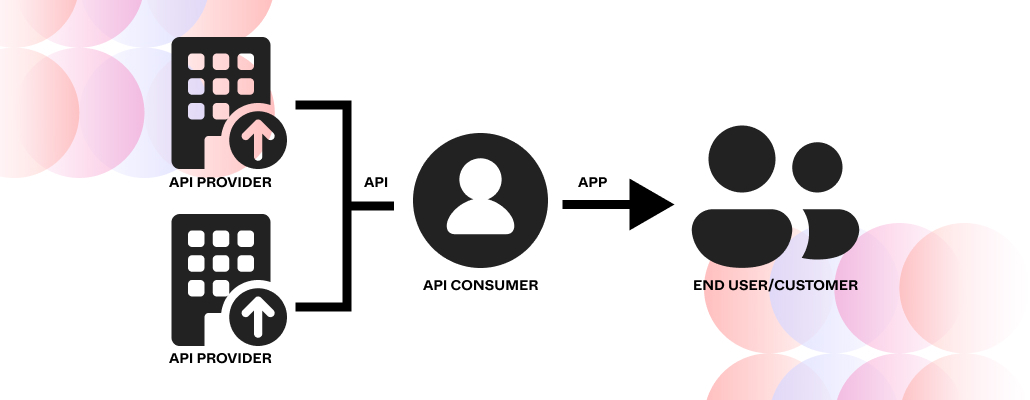

Customer Feedback Loops:

Lean development places a strong emphasis on customer feedback. It is implementing feedback loops throughout the development process. From initial concept testing to post-launch evaluations, ensures that the product remains aligned with customer expectations. However, this proactive approach to feedback minimizes the risk of developing a product that does not resonate with the target audience.

Conclusion

Lean Principles in Product Development offers a robust framework for streamlining product development processes. By applying these lean principles, organizations aim to optimize their operations, reduce waste, improve efficiency, and ultimately enhance customer satisfaction. The regulations can be adapted and applied in various ways depending on the specific context and industry.

Organizations can create a more efficient and adaptive approach to bringing products to market by emphasizing value-driven development, waste elimination, collaboration, and continuous improvement. Applying lean principles in product development is not a one-size-fits-all solution; instead, it requires a commitment to a cultural shift that prioritizes customer value, efficiency, and continuous learning. However, as industries evolve, integrating lean thinking in product development becomes increasingly crucial for organizations striving to stay competitive and innovative in the marketplace. Visit Tangent Blogs for more latest and upcoming product design and product development blogs.